Custom Engagement Solutions

Unlock tailored solutions with a free, no-obligation strategy session.

Expert Developers & Engineers on Demand

Scale Your Team with Skilled IT Professionals

Expert Guidance for Digital Transformation

Running an eCommerce business demands constant attention to cost, time, and internal systems. As order volume grows, small gaps in processes begin to drain cash without being obvious.

Slow fulfilment, repeated manual tasks, app overload, poor inventory planning, and rising return rates quietly increase operational expenses month after month.

For brands working on Shopify or Shopify Plus, these issues become even more visible once traffic improves and customers expect smoother experiences.

The good news is that cost reduction in eCommerce does not require cutting quality. It requires better use of data, simpler systems, and task automation in the right places. When your store is structured correctly, daily operations become lighter and more predictable.

This pillar guide shares practical, tried-and-tested methods that have been applied across Shopify stores to reduce operational cost while keeping store performance and customer satisfaction strong.

Before jumping into solutions, it helps to understand where money drains the fastest. Most brands notice problems only when margins drop, but the root issues begin much earlier.

Many stores run multiple paid apps that overlap in features. Heavy themes, old plugins, and scattered integrations increase the monthly subscription cost and demand more maintenance hours.

When fulfilment involves repeated manual steps—label creation, invoice printing, status updates—team hours multiply quickly. These delays increase customer queries, missed shipping slots, and overtime costs.

Overstocking ties up cash. Understocking creates lost sales and emergency restocking fees. Poor purchasing patterns are one of the biggest reasons brands lose liquidity.

Wrong carrier selection, poor zone mapping, or non-structured rate rules cause higher shipping charges for every order, especially during peak seasons.

High return rates increase handling time, repackaging expense, and customer service involvement. Most brands overspend here without tracking the root issues.

If your team answers repeated questions daily—order status, return steps, sizing queries—your support cost rises almost silently.

Understanding these cost drivers sets the stage for meaningful improvement. Each point below directly addresses one or more of these issues.

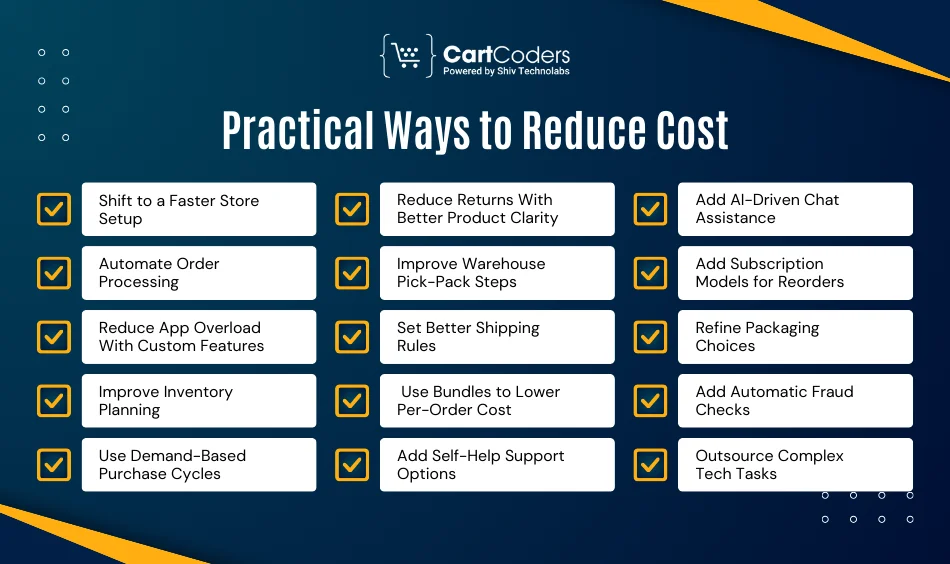

Reducing operational costs does not require drastic cuts. Most savings come from removing repetitive work, correcting hidden inefficiencies, and building systems that run smoothly on their own. The following methods are based on real patterns seen across Shopify stores, D2C brands, and mid-size retailers.

A slow or heavy store quietly increases operational burden. Every update takes longer, app conflicts happen more often, and support teams spend extra time fixing layout issues.

A faster setup reduces daily friction and long-term cost.

Key actions that help:

Impact on cost:

For many merchants, even a basic theme clean-up reduces maintenance costs for months.

Order processing is one of the highest recurring expenses in an eCommerce operation. When teams create labels manually, update tracking numbers by hand, or export sheets for every courier, the hours stack up quickly.

How automation cuts costs:

Result:

Team members spend less time on repetitive tasks, leading to faster fulfilment, fewer errors, and lower staffing costs.

Many stores install too many paid apps—often 10, 20, or even more. On Shopify, each paid app increases monthly fees and slows the store slightly. Frequently, two or three apps perform overlapping functions.

Replacing app stacks with custom features can:

Examples of custom replacements:

By removing unnecessary apps, stores often save hundreds of dollars annually and gain a faster, more stable setup.

Inventory affects not only storage cost but also cash flow. Poor planning leads to dead stock, emergency restocking, and blocked capital.

Ways to improve planning:

Savings achieved:

Even small improvements in planning can recover 10–20% of wasted stock cost.

A fixed purchasing cycle (weekly, monthly) does not suit fast-changing eCommerce behaviour. Demand-based cycles help brands buy inventory only when data indicates sufficient movement.

This approach benefits stores by:

Many D2C brands use this model and significantly lower their carrying cost.

Returns are expensive. They involve two-way shipping, repackaging, inspection, and support team involvement. Many returns happen due to unclear product details or mismatched expectations.

How to reduce return rates:

Why it matters:

When expectations match the actual product, return rates drop sharply. This saves both money and time for fulfillment teams.

Check out our services: Shopify Shipping Integration Services and Setup Experts

Warehouse inefficiency increases labour hours and error rates. The longer it takes to pick and pack orders, the higher the operational cost.

Ways to improve:

A refined pick-pack structure cuts handling time and reduces order mistakes, which also lowers return and replacement costs.

Shipping is often one of the biggest cost centres. Wrong courier choices, incorrect weight settings, and flat rates can cause recurring losses.

Shipping rules that help lower cost:

Better rules reduce overpaying for delivery and give customers predictable final pricing.

Every order has a processing cost—packing, courier charges, and support involvement. When customers buy more items per order, the cost per item decreases.

Why bundles reduce cost:

Bundles also encourage customers to buy more without heavy discounts.

Customer support teams spend a surprising amount of time answering the same questions: “Where is my order?” “How do I return this item?” “What size should I pick?”

A strong self-help experience reduces support tickets and lowers staffing costs.

Ways to implement self-help:

Cost impact:

Customers also appreciate quick solutions without waiting for human support.

AI chat systems help cut support costs without affecting service quality. These tools answer routine questions instantly, guide customers through the shopping process, and reduce dependency on manual help.

Benefits of AI chat in eCommerce:

Ideal use cases:

AI systems take care of 40–60% of daily queries for most stores, saving time and manpower.

Subscription-based selling is not just for beauty or health brands. Any store with repeat purchases—pet care, food, home essentials, grooming items, replacement parts—can reduce operational cost through stable reorder cycles.

How subscriptions reduce cost:

Popular subscription options:

With predictable volume, warehouses prepare more efficiently and reduce processing errors.

Packaging is often overlooked, yet it directly affects shipping and storage costs. Oversized boxes, unnecessary fillers, and non-standard carton sizes increase courier fees.

Ways to improve packaging:

Cost advantages:

Even small packaging adjustments can make a noticeable difference in monthly expenses.

Fraud and chargebacks drain revenue faster than most brands realise. Automatic fraud detection tools analyse orders based on behaviour, IP address, payment patterns, and other signals to prevent suspicious transactions.

Why does this reduce cost:

Examples of automatic checks:

A preventive system saves both time and money over the long term.

Not every task should be handled in-house. Trying to build or fix store features without proper skills leads to long hours, repeated mistakes, and a higher cost than hiring experts from the start.

Why outsourcing reduces operational cost:

Typical outsourced tasks:

We support brands with targeted development and automation work, allowing internal teams to focus on sales, fulfilment, and customer care.

When eCommerce brands start applying systematic changes—automation, better inventory practices, smarter shipping rules—the reduction in operational cost becomes visible within weeks.

While each store is different, the improvement pattern is consistent. The following comparison describes how costs shift once these methods begin to function.

Before:

Teams spend hours manually printing labels, updating tracking numbers, and handling fulfilment one order at a time. Errors increase during peak seasons, creating extra support tickets.

After:

Automation takes over repetitive work.

This reduces fulfilment hours and shortens delivery time.

Before:

Cash is stuck in slow-moving products. Overstock leads to increased storage fees. Sudden spikes in demand cause emergency restocking and higher purchase prices.

After:

Data-driven planning prevents unnecessary purchases.

This improves cash flow and reduces warehousing expense.

Before:

Flat shipping rules or incorrect courier selection increase the cost per order. Oversized packaging raises dimensional weight charges.

After:

Refined shipping rules pick the right carrier for each zone and order type.

Brands that review shipping logic often see immediate cost savings.

Before:

Agents answer repetitive questions daily, from return instructions to order status. During sale periods, support teams feel overloaded.

After:

Self-help and AI chat features handle common questions.

Support teams spend time only on complex cases, lowering overall staffing pressure.

Before:

Confusing product details lead to returns. Packaging issues cause damage. Incorrect sizing information pushes customers to request replacements.

After:

Clear information reduces return volume.

Return-related expenses drop, and customer satisfaction increases.

Different businesses experience cost reduction at different scales. The areas of savings, however, remain similar across store sizes.

Typical savings come from:

Observed savings range:

20–35% reduction in overall operational cost within the first 3–4 months.

Why? Smaller teams rely heavily on manual work. Replacing that manual effort with automation produces an immediate impact.

Key savings appear through:

Observed savings range:

18–30% reduction within 90 days.

Why? Mid-size brands usually have more SKUs and a wider customer base. Adjusting stock flow and shipping rules significantly reduces monthly expenses.

Cost reduction patterns become more strategic and include:

Observed savings range:

12–25% reduction, depending on scale and region.

Why? Enterprise brands already follow structured processes, so improvement comes from deep system refinement and automation.

Across our experience with Shopify and Shopify Plus merchants, the top savings areas are consistent:

Replacing flat rates with region-, weight-, and carrier-based rules is one of the fastest ways to reduce cost. Many stores overpay without knowing it.

Replacing 3–7 apps with one custom feature reduces monthly subscriptions and improves performance.

Automating the fulfilment pipeline reduces labour hours during peak sales and prevents repeated mistakes.

High-quality product details sharply reduce avoidable returns.

Adjusting purchase cycles around demand patterns opens up cash and reduces warehousing fees.

Cost reduction is not a one-time exercise. It strengthens the foundation of the store by making operations more predictable. When the system is lighter and more organised:

Brands that invest in operational refinement early grow with fewer interruptions and lower overhead.

CartCoders works closely with Shopify and Shopify Plus merchants to build friction-free systems that run with lower operational effort. Instead of focusing only on the store’s front-end, CartCoders – the best Shopify development agency assesses the complete operational chain.

Merchants see real savings because the work done focuses on structure, not quick patches.

Reducing operational cost is not only about lowering expenses—it is about building a system that supports stable growth. When fulfillment becomes faster, returns decrease, and inventory moves in a predictable rhythm, the entire store becomes healthier.

Cost control is ongoing, but once key processes are corrected, the long-term benefits are significant:

Brands that invest in operational improvement early enjoy smoother expansion as order volume increases. Contact CartCoders now because we continue to assist businesses in building setups that reduce unnecessary work and support consistent growth.

Automation is one of the strongest cost-saving methods. It removes repetitive tasks and reduces labour hours across fulfilment and support.

There is no fixed number, but many stores use more apps than needed. A short audit often reveals opportunities to replace several apps with one custom feature.

Yes. Slow stores require more fixes, face more customer complaints, and struggle with conversion drops. A faster setup reduces both technical overhead and support load.

When customers receive exactly what they expect, the return rate drops. Clear images, sizing details, usage notes, and comparison photos prevent confusion.

Yes. Even small stores benefit from automated shipping labels, tagging, and tracking updates. These improvements save time and prevent errors.

Quarterly reviews are ideal. This helps brands update shipping rules, check app expenses, revise purchase patterns, and refine workflows.

Projects delivered in 15+ industries.

95% retention rate, building lasting partnerships.

Serving clients across 25+ countries.

60+ pros | 10+ years of experience.