Custom Engagement Solutions

Unlock tailored solutions with a free, no-obligation strategy session.

Expert Developers & Engineers on Demand

Scale Your Team with Skilled IT Professionals

Expert Guidance for Digital Transformation

Shopify inventory planning means you decide what to stock, where to stock it, and when to reorder it. You also decide how much cash you tie up in products. If you plan well, you avoid stockouts. You also avoid piles of slow-moving stock.

AI fits into this job because inventory planning runs on patterns. Sales rise and fall by season. Certain SKUs sell in bundles. Some variants move fast. Others sit. Supplier lead times change. Returns spike after sales events. Manual planning misses many of these signals. Shopify AI Development helps you spot them sooner and act with fewer errors.

AI inventory management on Shopify does not replace basic inventory rules. It sits on top of them. It reads your sales history, stock levels, supplier lead times, and event calendar. Then it suggests reorder timing and reorder quantity. Many tools also help you create purchase orders, set stock alerts, and plan inventory across locations.

A manual process often looks like this:

That process breaks when your catalog grows. It also breaks when you sell through many channels or store stock at multiple locations. AI improves the workflow in three clear ways:

You still need to feed AI clean data. Garbage data produces garbage suggestions. Your first win comes from tracking the right signals and fixing common inventory errors.

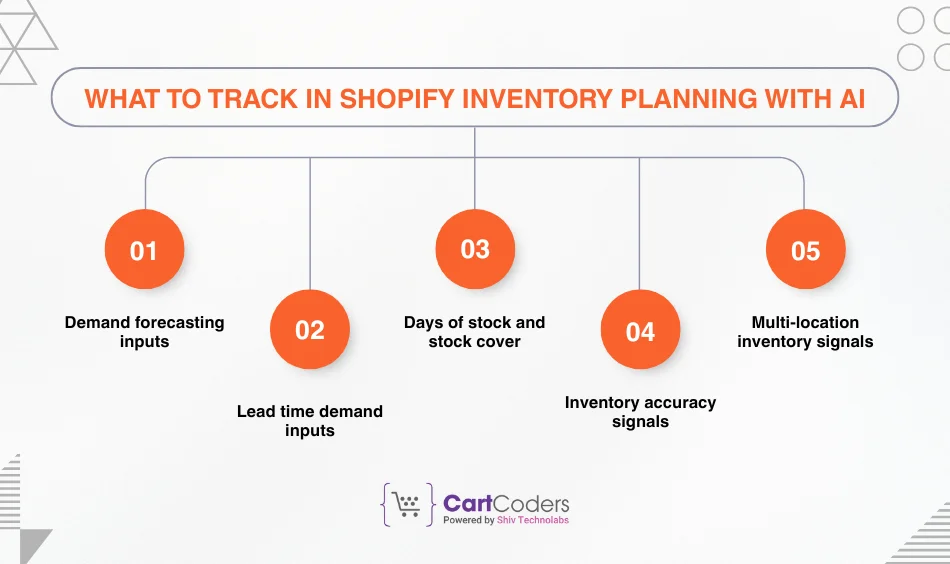

Think of tracking as building a “signal set.” Each signal answers a planning question:

Start with the following groups.

AI demand forecasting relies on consistent sales data. You should track:

If you run frequent sales events, keep a simple event log. You can store it in a sheet. You can also keep it inside a planning tool if it supports notes or event flags. This helps you explain sudden demand spikes.

Quick tip: Separate “organic demand” from “event demand.” AI can learn both, but you should label big events like Black Friday, clearance, or influencer pushes. This keeps the forecast from treating a one-time spike as normal demand.

Lead time demand answers one question: How much will you sell while you wait for replenishment?

To track it, you need:

Many stores store lead time in someone’s head. That creates reorder mistakes. Track lead time in days for each supplier, and review it monthly. Even a simple range helps. For example: “7–12 days” beats “about a week.”

Days of inventory on hand (also called days of stock) gives you a simple view of runway:

AI tools often show this as “stock cover.” It helps you plan by time, not just by units. It also helps you compare SKUs with different sales velocity.

Track days of stock by:

Forecasting fails when your available stock count lies. Inventory accuracy problems often come from:

Your goal is simple: Make “available” match reality. Track these accuracy signals:

Multi-location inventory adds a second planning layer: allocation. You might have stock in:

Track:

Allocation errors create silent stockouts. You might hold units, but in the wrong place. AI systems can suggest transfers when they see location demand differences. That only works when you track location data correctly.

| What to track | What it tells you | Why it matters for AI planning | Common mistake |

| Units sold per day (SKU + variant) | Sales velocity | Drives demand forecasting and reorder timing | Mixing variants into one number |

| Promo dates and discount depth | Event-driven demand | Helps forecast spikes and post-sale dips | Forgetting to label big promos |

| Supplier lead time (avg + range) | Replenishment delay | Shapes lead time demand and reorder point | Using one fixed lead time forever |

| Days of stock (by location) | Stock runway | Helps avoid stockouts and overbuying | Looking only at total stock |

| Stock adjustments and negative stock | Data health | AI suggestions depend on clean stock data | Adjusting inventory without reason codes |

| Returns processing time | Real available stock | Fixes false stockouts or false availability | Processing returns in batches too late |

| Multi-channel order flow | Overselling risk | Prevents double-selling the same unit | Delayed sync across channels |

You can start simple. You do not need a perfect system. You need a consistent one.

Sales data

Stock data

Supplier data

When you track these signals, AI forecasting becomes more useful. You reduce stockouts. You reduce overselling. You also make purchase order planning easier because reorder suggestions start to match reality.

If you want, share your store type (DTC or B2B), number of SKUs, and whether you run multi-location inventory. I’ll tailor the next section to the most common “fix” issues for that setup.

Inventory planning fails more often because of weak rules than weak tools. Many Shopify stores collect data but still face stockouts, overselling, or excess stock. These problems usually come from a few repeat mistakes. When you fix them, AI suggestions start to make sense and planning becomes stable.

The most common issues sit around reorder points, safety stock, stock accuracy, and overselling. These areas decide whether forecasts turn into action or stay as charts.

A reorder point tells you when to reorder, not how much. Many stores treat it as a fixed number. That approach works only when demand and lead time stay flat. In real stores, both change often.

Reorder point problems usually come from one of these:

A simple reorder point calculation looks like this:

Reorder point = average daily sales × lead time (in days)

That formula gives a base level. It does not protect you from delays or demand jumps. This is where many stores run into stockouts even when they “reordered on time.”

AI systems do not rely on one static number. They look at:

Instead of asking “Have we hit the reorder point?”, AI asks “Will we hit zero stock before the next delivery arrives?”

This shift matters. It turns reorder points into early warning signals rather than last-minute alerts.

Safety stock acts as a buffer. It protects you from late suppliers and demand swings. Many stores misuse it.

When safety stock stays too high, cash gets locked in slow-moving stock. When it stays too low, stockouts rise.

These two concepts serve different jobs:

| Item | Purpose | Key question it answers |

| Safety stock | Risk buffer | “What if things go wrong?” |

| Reorder point | Timing trigger | “When should I reorder?” |

Safety stock does not decide when you reorder. It decides how much risk you can absorb. AI systems often adjust safety stock by SKU based on demand volatility. Fast and stable sellers need less buffer. Unstable or seasonal items need more.

Lead time demand tells you how many units you will sell while waiting for replenishment. Errors here do not show up right away. They show up weeks later as sudden stockouts.

A supplier that usually ships in 7 days might take 12 days during peak season. If your system still plans for 7 days, your reorder timing breaks.

AI models work better when lead time data includes ranges, not just averages. Even a simple “best case” and “worst case” helps planning logic stay realistic.

AI forecasting depends on clean stock data. If your available stock is wrong, forecasts drift away from reality.

When stock accuracy drops, you may see:

These problems feed bad signals into AI systems.

Start with simple rules:

Once accuracy improves, forecasting and reorder suggestions improve without any other changes.

Overselling hurts trust. It also creates reactive planning. Many Shopify stores face this when they sell through more than one channel or location.

Overselling also creates false demand signals. AI may read oversold units as real demand, which leads to overbuying later.

AI tools often help by:

These actions work only when selling rules stay clear and consistent.

| Problem area | What usually goes wrong | Impact on planning | What to fix first |

| Reorder point rules | Static values | Late reorders and stockouts | Track lead time and demand changes |

| Safety stock | One-size buffer | Cash locked or stockouts | Adjust by SKU volatility |

| Lead time demand | Old supplier data | Hidden stock gaps | Track ranges, not guesses |

| Inventory accuracy | Delayed updates | Bad forecasts | Process returns and audits |

| Overselling | Channel sync gaps | Customer issues | Reserve stock early |

| Multi-location stock | Poor allocation | Wrong stock in wrong place | Set clear location rules |

Many store owners try new forecasting tools without fixing these basics. The result feels disappointing. Forecasts look smart, but outcomes do not change.

When you fix reorder logic, safety buffers, accuracy, and overselling, AI starts working as intended. Forecasts align with reality. Reorder alerts arrive earlier. Purchase order planning becomes calmer. Firefighting drops.

Inventory planning then shifts from reaction to control. You spend less time checking stock levels and more time planning growth.

Automation in Shopify inventory planning usually starts with forecasting. It then moves into replenishment, purchase orders, and allocation. Each layer builds on the previous one.

Demand forecasting answers one question: How many units will sell in the coming days or weeks?

Manual forecasting often relies on averages. AI-based forecasting reacts to change faster.

Automated forecasting tools usually track:

Instead of giving one number, AI often provides a range. This range reflects uncertainty. It helps planners decide how much risk to take.

Demand does not change once a month. It changes daily. Automation allows forecasts to refresh as new data arrives. This keeps reorder timing aligned with reality.

When forecasts update often, you avoid two issues:

Automated forecasting works best when it feeds directly into reorder rules. A forecast without action still leaves work on your plate.

Reorder timing decides when a reorder alert should fire. Manual alerts often trigger too late. Automation helps move the alert earlier.

Reorder timing automation usually combines:

Instead of checking “stock below X,” the system checks “days of stock left versus days until next delivery.”

This approach reduces last-minute decisions. It also gives teams time to react when suppliers delay shipments.

Automated timing works best when safety stock rules stay realistic. Overly high buffers still cause overbuying, even with automation.

Knowing when to reorder solves only half the problem. You also need to know how much to reorder.

Manual reorder quantity decisions often rely on gut feeling. Automation replaces this with demand-based rules.

AI-based systems often suggest a reorder quantity that covers a defined future window, such as 30 or 45 days. This window can change by SKU based on demand stability.

Overordering often happens when teams panic after stockouts. Automation smooths this behavior. It bases reorder size on forecasted need, not fear.

This also improves cash flow planning. You place more frequent, smaller orders instead of large reactive ones.

Purchase orders connect planning to suppliers. Manual PO creation slows teams down and invites errors.

Automated purchase orders can:

This reduces admin work. It also creates a clear trail of inbound stock.

When purchase orders stay linked to forecasts, you gain visibility:

Automation does not remove human control. Teams can still review and approve orders before sending them.

Multi-location inventory adds complexity. Automation helps place stock where it sells best.

AI systems can suggest stock transfers instead of new purchases. This helps use existing stock before ordering more.

Allocation automation works only when location rules stay clear. Each location must have a defined role.

Overselling creates customer issues and planning noise. Automation reduces this risk.

Automated systems help by:

This keeps available stock closer to reality. It also improves forecast accuracy by removing false demand signals.

| Automation area | Manual risk | Automated benefit | Result |

| Demand forecasting | Slow updates | Frequent forecast refresh | Better reorder timing |

| Reorder alerts | Late reactions | Early warnings | Fewer stockouts |

| Reorder quantity | Guesswork | Demand-based sizing | Lower excess stock |

| Purchase orders | Admin errors | Pre-filled, linked POs | Faster ordering |

| Stock allocation | Manual transfers | Smart location suggestions | Lower shipping cost |

| Overselling prevention | Sync delays | Early stock reservation | Fewer order issues |

Automation should follow rules, not replace judgment. Set clear limits:

These limits keep teams in control while still saving time.

Before automation, teams check stock levels often. They react to alerts late. They rush orders. After automation, work shifts to review and planning.

Teams spend less time counting units and more time reviewing exceptions. This leads to calmer operations and fewer surprises.

In the next section, the focus moves to planning for special cases. This includes new products, seasonal demand, and sales events. These scenarios test inventory systems the most and reveal how strong your planning rules really are.

Inventory planning feels easy when sales stay steady. It becomes harder when demand shifts fast, new products launch, or large sales events hit. These moments test whether your planning rules truly work. AI helps most in these edge cases because it reacts faster than manual checks.

This section focuses on special scenarios that often break inventory planning and how AI-driven planning keeps control without chaos.

Seasonal demand creates uneven sales patterns. Some SKUs sell fast for short periods. Others stay quiet most of the year. Treating both the same causes problems.

Seasonal items need tighter planning windows. AI systems look at how demand rises and falls, not just how much sold last year.

AI models track:

This helps you reorder earlier when demand starts climbing and slow down sooner when demand fades. The result is fewer stockouts during peak weeks and less leftover stock after the season.

Sales events change demand behavior. Customers buy faster. They also buy in bundles. Planning for these events requires different rules.

Events like clearance sales or major discount periods compress demand into a short window. Planning must account for speed, not just volume.

AI systems read:

This allows planners to adjust reorder timing before stock hits zero. It also helps reduce overbuying after the event ends.

New products create a planning gap. There is no sales history. Many teams guess and hope for the best.

AI cannot predict exact demand for new items. It can still guide decisions by using similar product data.

AI tools often compare:

Early sales matter more than forecasts here. AI adjusts quickly when real data appears. This allows fast correction before stock issues grow.

Bundles create hidden inventory risks. A single bundle sale affects multiple SKUs. If tracking breaks, stock counts lie.

These issues cause silent stockouts. You may see bundle stock available while one component has already run out.

AI systems track:

This helps planners reorder components before bundles break. It also helps adjust bundle availability during low stock periods.

Multiple warehouses improve delivery speed. They also add planning complexity.

Without allocation logic, stock sits in the wrong place.

AI-based planning systems watch:

Instead of reordering new stock, the system may suggest moving units from one location to another. This improves service without raising inventory levels.

Returns change available stock. Many plans ignore them.

Ignoring returns makes stock appear lower than it is.

AI systems factor in:

This helps forecasts stay closer to reality and avoids unnecessary reorders.

| Scenario | Main risk | What AI helps with | Planning benefit |

| Seasonal demand | Overbuy or late reorder | Early trend detection | Better peak coverage |

| Sales events | Sudden stockouts | Real-time demand shifts | Fewer missed sales |

| New products | Guess-based ordering | Similar product modeling | Faster correction |

| Bundles and kits | Hidden stockouts | Component tracking | Stable bundle sales |

| Multiple warehouses | Poor allocation | Transfer suggestions | Lower fulfillment cost |

| Returns | False low stock | Restock-aware planning | Fewer unnecessary orders |

Strong Shopify inventory planning follows clear rules:

AI does not remove responsibility. It removes blind spots. When planning rules stay clear and data stays clean, AI turns inventory into a controlled system instead of a daily struggle.

Shopify inventory planning with AI uses sales data, lead time, and stock levels to predict demand and guide reordering. It helps stores decide what to reorder, when to reorder, and how much to reorder. This reduces stockouts, overselling, and excess inventory.

Yes. AI improves Shopify inventory forecasting by tracking demand changes in near real time. It adjusts forecasts based on sales velocity, seasonality, and promotions. This helps stores react faster than manual planning methods.

AI calculates reorder points by combining forecasted demand, supplier lead time, and buffer stock needs. It adjusts safety stock based on demand volatility instead of using a fixed number. This lowers risk without locking extra cash in inventory.

AI helps reduce overselling by reserving stock when orders are placed and syncing inventory faster across channels and locations. It also flags SKUs that are close to running out. This keeps available stock closer to reality.

Yes. Small Shopify stores benefit from AI inventory planning because it reduces manual work and planning errors. Even with a small catalog, AI helps track demand trends, set better reorder timing, and avoid common stock issues as the store grows.

AI inventory planning needs sales history, current stock levels, supplier lead time, and location data. Promo dates and return patterns also improve accuracy. Clean and consistent data leads to better forecasts and reorder suggestions.

Shopify inventory planning works best when decisions rely on data instead of guesswork. Tracking the right signals, fixing weak rules, and automating key actions creates stability. AI helps turn inventory planning into a controlled process rather than daily firefighting.

As Shopify stores grow, manual planning becomes harder to manage. AI-driven inventory planning supports smarter forecasting, better reorder timing, and smoother stock flow across locations and channels.

At CartCoders, we help merchants build advanced Shopify AI Development solutions that connect forecasting, inventory logic, and automation into one system. The goal stays simple: fewer stockouts, less excess inventory, and better control as your store scales.

If you want Shopify inventory planning that actually works in real selling conditions, AI-backed systems make the difference.

Projects delivered in 15+ industries.

95% retention rate, building lasting partnerships.

Serving clients across 25+ countries.

60+ pros | 10+ years of experience.